How to Understand the Difference Between HRV & ERV Ventilation

If you’re interested in increasing the indoor air quality for your Chicagoland home, then it’s important to learn about the difference between HRV and ERV ventilation. HRV and ERV ventilation systems bring balance to unbalanced household air.

Short for “heat recovery ventilation” and “energy recovery ventilation,” HRV and ERV ventilation technology has been partially driven by the trend toward more stringent building standards to save energy, as well as a concurrent concern about the health of the indoor environment.

The increasing focus on the need to enhance household ventilation is evidenced by recent changes in the residential ventilation standards published by the American Society of Heating, Refrigeration and Air Conditioning Engineers (ASHRAE). Since 2003, ASHRAE’s recommended ventilation rate was 7.5 cubic feet per minute (CFM) of fresh air per occupant in the home, plus 1 CFM for each 100 square feet of floor space. However, beginning in 2013, the decade-old ventilation bar was raised to 3 CFM per 100 square feet.

While that change may appear insignificant at a glance, for a 2,400-square-foot home with four occupants, the new formula boosts the total recommended ventilation rate from 54 CFM to just over 100 CFM—a substantial increase of almost 90 percent.

The goals of adequate ventilation are simple but not easy. It ensures that fresh outdoor air enters the house at an adequate volume and with predictable frequency, as well as removing or reducing the concentration of fumes and odors. Ventilation should also take out airborne pollutants and keep indoor humidity in the optimum range for health and comfort.

Ventilation Then & Now

In the past, adequate residential ventilation happened mostly by accident. When energy costs were low, so were construction standards relating to the airtightness of homes. Most houses breathed through structural cracks and gaps in amounts sufficient to allow fresh outdoor air to infiltrate and dilute the accumulation of indoor pollutants and fumes.

ASHRAE’s new higher ventilation standard recognizes the widespread changes in both new home construction and upgrades to existing structures to make them more energy efficient. As new high performance houses are built more airtight to conserve heating and cooling, and as homeowners take measures to seal houses originally built to lower standards, these under-ventilated residences become reservoirs of stagnant air and accumulated pollutants, fumes and humidity. The status quo has worsened rapidly, so the Environmental Protection Agency (EPA) now finds that the air inside many homes is on average 10 times more polluted than the outdoor air.

Mechanical Approaches

Standard mechanical ventilation provides some relief to the problems of under-ventilated homes. Exhaust fans aren’t new; they simply pull indoor air into vent ducts and exhaust it outdoors. This exhaust-only approach has its drawbacks. As stale air is removed, replacement fresh air may enter the house in adequate volume, or not. When sufficient fresh replacement air doesn’t flow in, the house is depressurized and air from elsewhere — like the attic, crawl space or other unhealthy zones — continuously infiltrates to equalize the pressure differential. Air quality suffers and the house becomes unpredictable to heat or cool and keep comfortable.

One-way mechanical ventilation inducts unconditioned outdoor air at temperatures that burden your air conditioner or furnace and increase cooling and heating costs. Exhaust-only ventilation definitely has its place, but mainly in isolated applications, such as exhausting cooking fumes from the kitchen or water vapor from bathrooms.

HRV & ERV Ventilation: A Balanced Idea

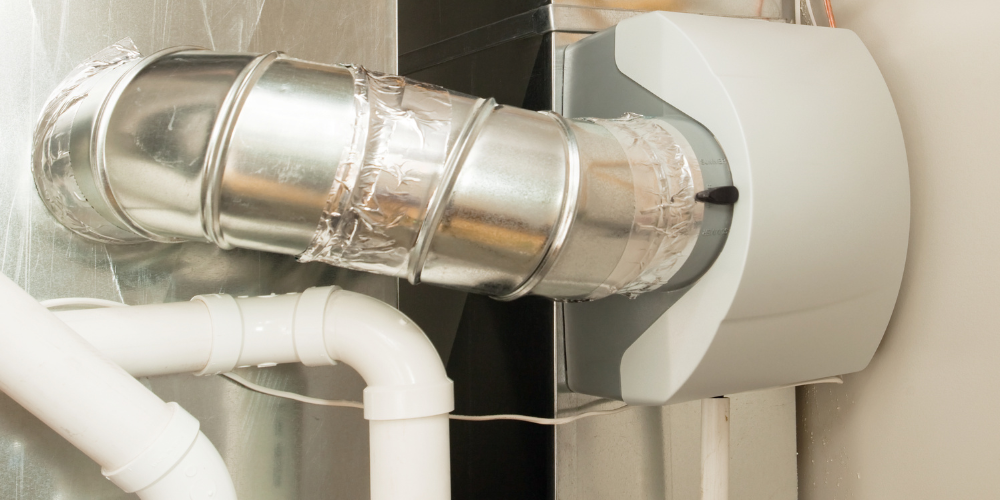

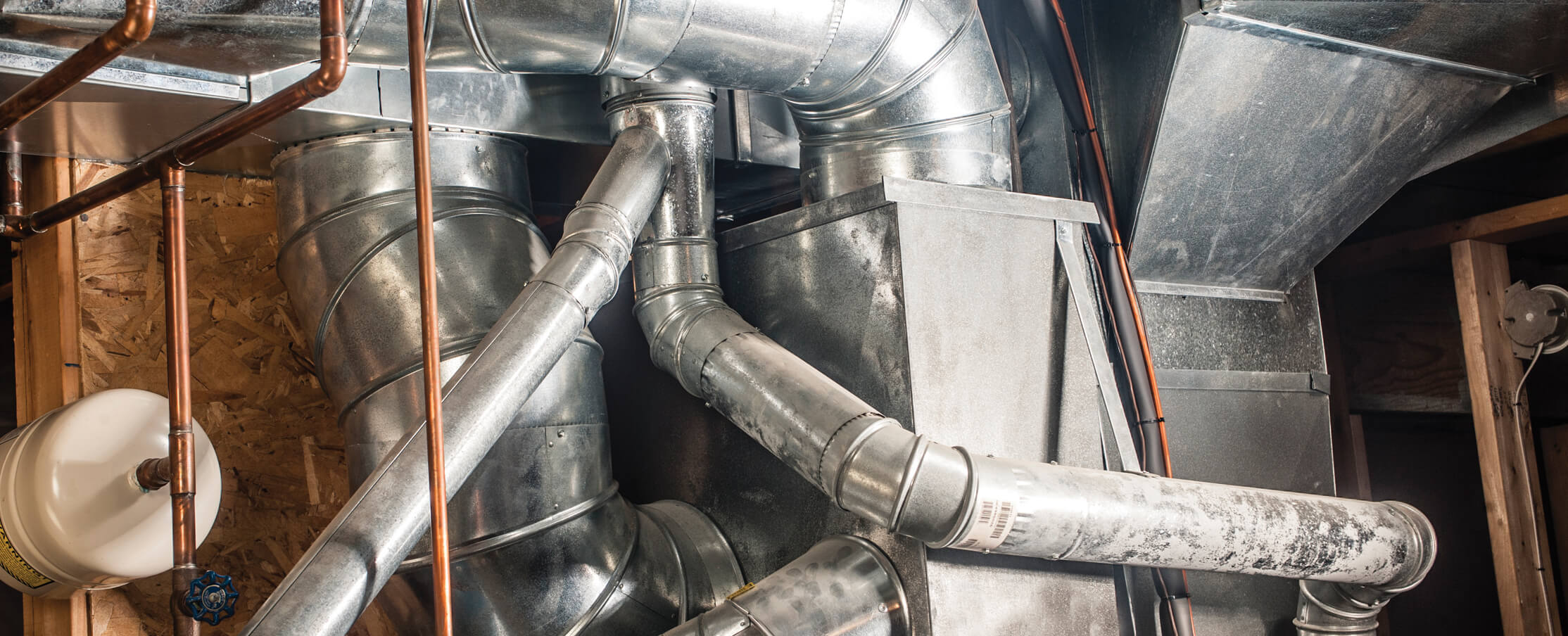

The one-way approach to mechanical ventilation has been updated for the 21st century into a balanced, whole-house approach. HRV and ERV ventilation systems induct fresh, filtered outdoor air into the house while exhausting stale, polluted indoor air at exactly the same rate. Utilizing small-diameter dedicated ductwork or your existing HVAC ducts if preferred, along with a central unit that incorporates intake and exhaust fans plus a heat exchanger, these systems run continuously at a selectable speed and rate of air exchange.

Stale indoor air is removed from areas like the kitchen and laundry room while an equal volume of fresh outdoor air is delivered to bedrooms and living areas. Because the exhaust and intake volumes are balanced, indoor air pressure remains neutral, not depressurized as with conventional exhaust ventilation.

Exchanging Heat & Air

Both the HRV and ERV ventilation systems also address another longstanding downside of ventilation: excessive heat loss or heat gain, depending on the season. Throwing open windows and flooding the house with frigid outdoor air in the middle of a typical Chicago winter may indeed freshen the indoor environment, but it will also send heating costs through the roof, not to mention severely impact indoor comfort. To prevent temperature swings due to the effects of ventilation, the central controller in HRV and ERV ventilation incorporates a heat exchanger mounted between the intake and exhaust air streams. Heat energy naturally flows from a warmer area into a cooler area. While the incoming and outgoing air streams are entirely separate and never mix, heat from the warmer air stream transfers into the cooler air stream.

What does this mean for your summer and winter comfort? During summer, outdoor heat in the incoming air stream is extracted by the heat exchanger and added to the exhaust stream. As much as 85 percent of the heat is removed from outdoor air, vastly reducing the impact on your air conditioner. In winter, the process reverses. The outgoing air is warmer, so heat flows in the opposite direction and is added to incoming fresh air stream to pre-heat it. This helps maintain indoor temperatures and lowers heating costs.

What About Humidity?

Maintaining indoor humidity in the recommended range of 30 percent to 50 percent while also bringing in fresh outdoor air can be difficult, no matter what season. In summer, outdoor air is often especially humid and makes the indoor environment feel muggy. Humid air holds heat more effectively, so your A/C runs longer cycles to maintain desired indoor temperature settings. Costs rise and comfort levels suffer. During winter, inducted outdoor air often contains extremely low-humidity content and ventilation may add to the familiar discomforts of dry air indoors.

An energy recovery ventilator performs the same heat exchange functions of an HRV. However, it also incorporates technology to transfer humidity between air streams. Utilizing a process called “enthalpy transfer,” the ERV extracts water vapor from the more moist air stream and adds it to the drier air stream. In summer, humidity is removed from incoming air and dumped into the outgoing airstream, reducing the effect of outdoor humidity on the indoor environment. In winter, the process reverses, helping sustain humidity levels to prevent overly dry indoor conditions.

While an ERV offers some humidity control, experts caution that these units are not dehumidifiers. Where humidity levels outdoors are persistently high, installing an HRV and a standalone dehumidifier may be a more effective measure to keep indoor humidity in the comfort zone than an ERV. Where humidity is lower, or where the option of an additional dehumidifier isn’t preferred, energy recovery ventilation may be the preferred choice over heat-recovery ventilation.

Keeping Costs Low

If a balanced mechanical system like HRV and ERV ventilation increases household electrical consumption and monthly energy expenses significantly, all the goals of an optimum system haven’t been adequately met. Fortunately, while standard mechanical vent fans typically rely on permanent split capacitor (PSC) motors with high electrical demands, today’s HRV and ERV ventilation systems utilize highly efficient electronically commutated motor (ECM) technology that sips electricity. Running continuously at low air volume, a heat recovery ventilator can consume as little as 13.5 watts. That’s about as much electricity as a single compact fluorescent light bulb.

Regular Upkeep

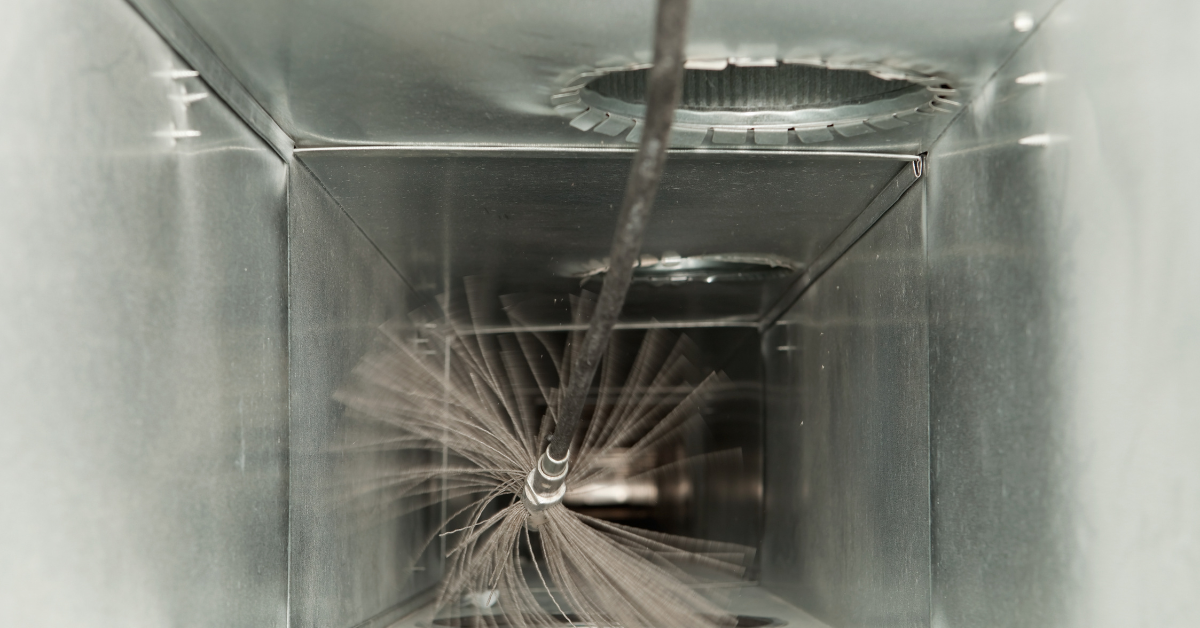

Maintenance requirements of HRV and ERV systems are also minimal and very DIY-friendly. In a typical unit, the central controller houses two washable filters that should be removed and rinsed under hot water every three months. While the filters are out, the surfaces of the internal core that incorporates the heat exchanger, and in most ERVs, also the humidity exchange core, are also vacuumed with a soft brush attachment to remove dust.

For more information on the air quality and indoor comfort benefits of HRV and ERV ventilation, check out Black Diamond Plumbing & Mechanical’s ventilation solutions, or call 815-444-0979 .

Image via Flickr by eflon

Recent Posts

Request Service

Please fill out the form and we will get in touch with you shortly. We look forward to serving you!

Request Service

Proudly Serving

The Chicagoland AreaAddison | Algonquin | Antioch | Arlington Heights | Aurora | Barrington | Bartlett | Batavia | Beloit | Belvidere | Bensenville | Bloomingdale | Bolingbrook | Buffalo Grove | Byron | Caledonia | Capron | Carol Stream | And Much More!

VIew ALL